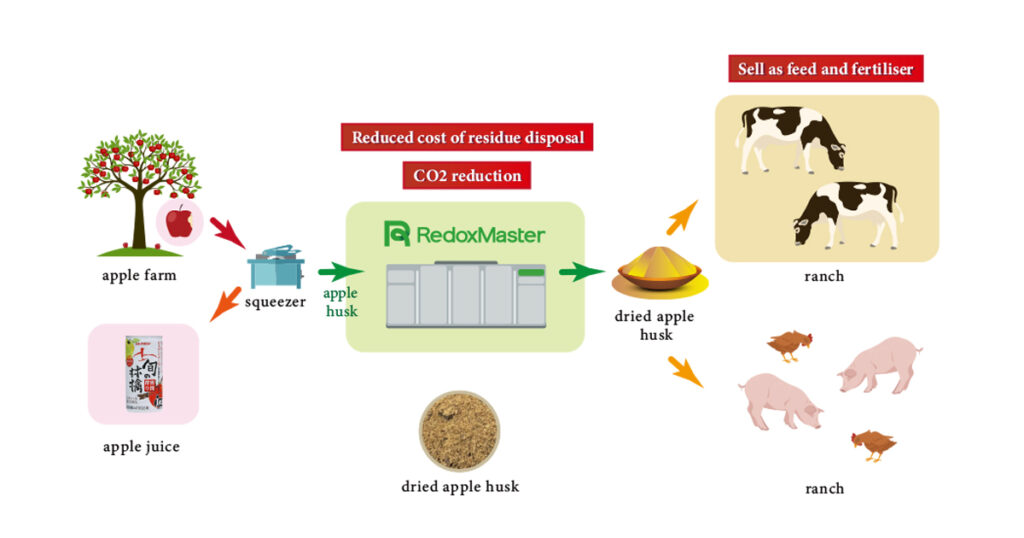

the RedoxMaster has succeeded in drying apple pomace while reducing CO2 emissions, and turning it into animal feed.

JA Aoren is one of the largest producers of apple juice in Japan. RedoxMaster has been installed in its factory from 7 years ago and apple juice residues have been dried by the machine with no major problem. The dried residue is processed into high-performance livestock feed that improves the health of cattle and bioplastic material. The RedoxMaster can dry organic waste at low temperatures of less than 100°C, so the running costs of the drying process are significantly lower than with conventional technologies. In addition, by using the heat source of the existing boiler in Aoren’s plant, drying costs can be further reduced. The residue of the apple juice pomace dried at low temperatures by the RedoxMaster contains undamaged polyphenol content, thus, the dried residue is sold as a high value-added supplement feed ingredient that improves cattle health and meat quality.

The treated apple pomace has a moisture content of less than 12.5%, so this residue can be stored for a long time. The lower weight also makes it easier to transport, which helps ESG management by significantly reducing the amount of carbon dioxide emissions from the drying and transportation of apple pomace. By drying apple pomace with RedoxMaster, which used to be disposed with high treatment cost, it is now possible to sell them to feed companies as high-quality and high-value-added feed.

Work Flow

CASE STUDY PDF DOWNLOAD

Click here to download this case study PDF file.