Production and sale of dried green tea pomace and coffee bean pomace as raw material for cattle feed and biomass plastics at the Gunma Plant of Nihon Canpack Co., LTD.

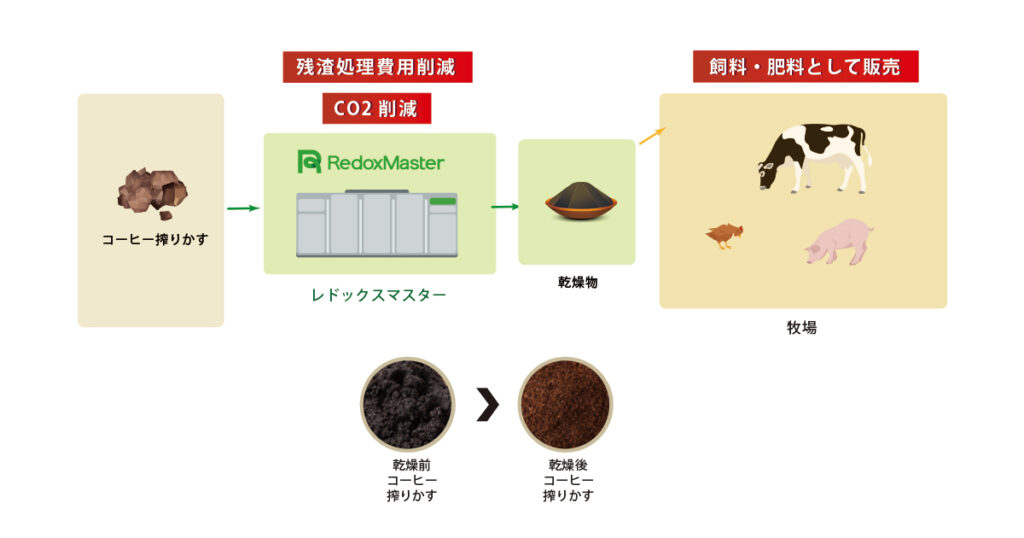

Since 2020, two RedoxMaster® machines have been installed at the Gunma Plant of Nihon Canpack Corporation, one of the largest beverage filling companies in Japan, to dry green tea and coffee drained lees. The dried green tea and coffee drained lees are purchased by Glencal Senary Co., Ltd. a subsidiary of Glencal Technology, and sold as a raw material for high-performance feed to improve cattle health and for biomass plastics. The beverage filling company has not only reduced the cost of treating green tea and coffee bean waste, which used to be disposed of at high cost, but also made it possible to sell them as high-value-added products.

The problem of plastic waste is becoming more serious all over the world, and the Japanese Government has set policy targets to increase the production of biomass plastics due to stricter targets for reducing the use of petroleum-based plastics, but the drying of biomass by conventional high-heat methods, is costly and consumes significant amounts of energy and emits large amounts of carbon dioxide. Therefore, making bioplastic products economically and environmentally is unviable in many cases. However, drying with RedoxMaster® largely improves the dryness degree of the treated biomass and the processing time. As a result, biomass treated with RedoxMaster® becomes homogeneous and granular, while biomass treated by centrifugal separation or high-heat treatment is carbonised and oxidised, becoming lumpy, irregular in size and prone to deterioration. Such biomass cannot become high-quality material for biomass plastics. One of the major advantages of the our method is that the raw material retains the original robust properties of the plant. It goes without saying that the low-temperature treatment does not use significant thermal energy, which significantly reduces carbon dioxide emissions.

Biomass plastic products made from biomass material treated with RedoxMaster® include logistics pallets for UPR Co., Ltd., food trays used in a major American coffee chain. Because the biomass is dried and treated without carbonisation or oxidation by RedoxMaster®, the products have excellent strength and heat resistance, which conventional bioplastic products could not achieve.

We also produce biomass plastic cones for construction sites and sell them to the construction company which is a group company of Japan Railways. Although construction industries has not been environment-friendly, they should be greener due to the recent trend of ESG management and the pressure from the government. Therefore, these cones are attracting a lot of attention from the industry and it is expected that the products will be used all over the country.Due to the recent rise in overall commodity prices, the selling price of dried coffee bean residue and green tea residue as feedstock and biomass plastic material is also on the rise. Accordingly, this business model is becoming more lucrative recently.

Work Flow

CASE STUDY PDF DOWNLOAD

Click here to download this case study PDF file.